This machine is used for heating, sterilizing, insulating and cooling for fresh milk, fruit juice, fruit beverage, alcohol etc. This unit is also used for pasteurizer (widely used in fresh milk, milk beverage, juice, tea, alcohol, ice cream etc.) and also pre-sterilizing material when producing pasteurized milk (long shelf life milk).

Product Description

Deepora Food Machinery(Shanghai)Co.,Ltd is a professional machinery manufacturer based on technical developing. Combining with R&D, manufacturing, installation debugging and training, we are engaged in producing the liquid projects used in Dairy,Fruit &Vegetable juice,Beverage,Tea,Brewing,Flavoring,Pharmacy,Egg,Bone & Meat processing and Daily chemical products etc.

Milk Processing Equipment , PID Control Milk Pasteuriser Machine

Plate Pasteurization 3 Sections with PLC Touch Screen and PID Control

Usage:

This machine is used for heating, sterilizing, insulating and cooling for fresh milk, fruit juice, fruit beverage, alcohol etc. This unit is also used for pasteurizer (widely used in fresh milk, milk beverage, juice, tea, alcohol, ice cream etc.) and also pre-sterilizing material when producing pasteurized milk (long shelf life milk).

Structure:

This unit can be connected with separator, homogenizer, flash evaporator & degasser etc.

Control type:

Full automatic control with PLC touch screen or semi-automatic control with PID control.

Standard attachments:

(1). Plate heat exchanger

(2). Material balance bucket

(3). Hot water balance drum

(4). Hot water pump

(5). Product pump

(6). Steam & water mixer

(7). Electricity box

(8). Stainless steel pipes and valves etc.

(9). PLC and color touch screen

Features:

This machine has features of high heat recovery lower energy cost, strict design on the construction and easy operation, simple maintenance.

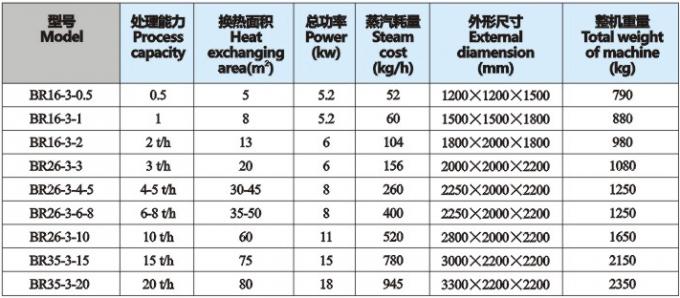

Technical parameters:

5°C→65°C (homogenization)→85°C(15s)→5°C